In addition to having trouble hiring, the business is waiting on CHIPS Act financing.

For TSMC’s new facilities in the Arizona desert, which are already struggling to function properly, the bad news just keeps piling up. Because of a lack of available workers, the company had previously declared that the production capacity of its 4nm factory will be delayed by at least one year. The company’s Chairman has now indicated that the construction of its second site would also be delayed until either 2027 or 2028, which is negative news for the company’s intentions to expand in the United States. Because of the delays, the corporation may also need to reevaluate the entire operation, taking into consideration the timescales that are involved.

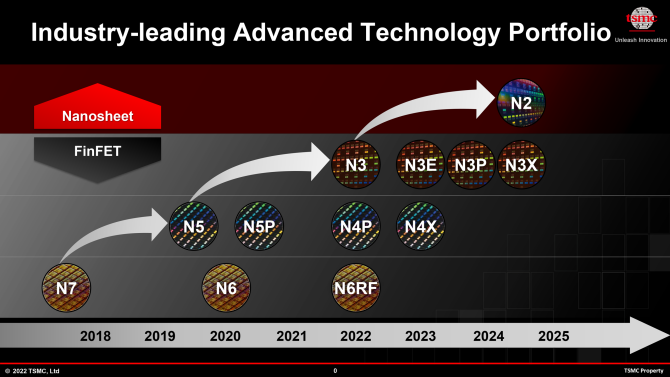

This week, the senior brass of the corporation took part in an earnings call with investors and altered their projections for the operations that are being carried out in Arizona. The second facility of the company, which is now being constructed to manufacture wafers with a 3nm process, will be delayed by one year, from 2026 to 2027 at the earliest, according to officials of another company. However, Chairman Mark Liu added a new ripple to the factory’s destiny when he stated that it might not be a 3nm facility after all. Mr. Liu made this statement in light of the delays that have occurred and the fact that funding from the CHIPS Act have not yet been made available. The remarks made by Chairman Liu were highlighted in a story that was published by Bloomberg.

During the results call, Liu indicated that the output of the second facility will be determined by the requirements of the customers as well as the funding provided by the government. In the event that there are sufficient subsidies, it will be able to produce cutting-edge wafers with a size of 3 nanometers or less, and if there are not enough subsidies, it will be 4 nanometers or somewhere in the vicinity. “Our decisions regarding overseas operations are based on the requirements of our customers as well as the required level of government subsidy or support,” Liu stated during the call.

As a whole, it appears that the domino effect is taking place in Arizona, with delays at the first facility creating delay at the second plant, which in turn causes the second plant to fall behind schedule. In addition, the money set out for the CHIPS Act have been arriving at a startlingly slow pace. However, the first payout did not take place until December 2023, despite the fact that the bill was signed into law in late 2022. The amount of money that was distributed was just $35 million out of the total of $52 billion that was designated. Significant chip manufacturers, like Intel, Samsung, and TSMC, have not yet received financing from the act as of yet.

Whether or not this apparent fiasco ever gets back on track is something that we will have to wait and see. Despite the fact that TSMC would never publicly admit to having such a goal in mind, it appears that the decision was made with the intention of diversifying its production stream in order to ensure its future in the event that China invades Taiwan. Customers like Apple would also be able to claim that they were utilizing silicon that was manufactured in the United States, which would be a first for the industry. Despite the fact that such a move would be beneficial to marketing, it has been stated that chips manufactured in the United States would cost up to thirty percent more than those manufactured in Taiwan because to higher labor and construction costs. This indicates that every aspect of TSMC’s operation in the United States is riddled with difficulties.