In 2021, the corporation initially declared that it would be expanding into New Mexico.

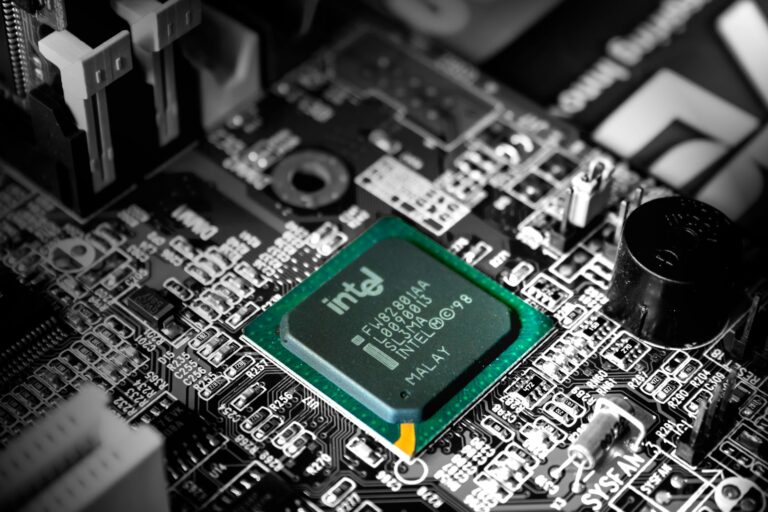

At this very moment, Intel is celebrating the opening of a brand new facility in New Mexico that is known as Fab 9. Two years ago, the corporation made the announcement that the project would cost $3.5 billion, and now it is fully open for business. The facility is designed to meet the most advanced packaging requirements of Intel, including the company’s Foveros technology, which is a three-dimensional chip stacking technology. It will be combined with the existing Fab 11X that the corporation has in order to increase the amount of sophisticated packaging that Intel produces.

In Rio Rancho, New Mexico, which is a suburb of Albuquerque, the new facility has been constructed. According to the firm, the new unit is the only factory in the United States that is capable of generating innovative packaging on a large scale. Plans for the New Mexico facility were initially revealed in May 2021, immediately following the reinstatement of CEO Pat Gelsinger to the leadership of the firm and the transition to the IDM 2.0 strategy of “five nodes in four years.” For that to be possible, it would require certain technologies to be operational in the future, and as a result, we are currently in this position.

According to Intel, the new fabrication facility is devoted to Foveros and EMIB, which are packaging technologies that are utilized on the company’s most cutting-edge tile-based (or chiplet) designs. The company’s “Meteor Lake” Core Ultra mobile chips, which make use of Foveros for three-dimensional stacking, and EMIB (Embedded multi-die interconnect bridge), which joins chiplets that are stacked next to one another on a two-dimensional substrate, are current examples of this. Ponte Vecchio, the company’s most advanced graphics processing unit (GPU) for data centers, utilizes both technologies. Intel has stated that the fab will be generating Foveros designs for its own requirements; nonetheless, this is not only a significant accomplishment for the company’s foundry service, but it will also strengthen the company’s resilience to worldwide disruptions such as the one that occurred with COVID-19.

Rio Rancho has been home to Intel’s Fab 11X for many years, and the company’s Fab 9 is located in the same building. In the previous year, Intel made the announcement that it would be receiving a fresh coat of paint. At the same time, the business decreased its manufacturing of 11X from 90nm to 45nm by more than one billion dollars. Over the course of the year, Intel has made significant investments in both of these locations as part of its efforts to strengthen its fabrication capabilities in order to aggressively compete with TSMC. It is not a coincidence that TSMC has announced its own investment of $2.9 billion to expand its capabilities in advanced packaging.