The price is comparable to that of conventional lithium-ion batteries.

The commercial development of solid-state batteries has a history of making false promises that would make Tesla’s fully autonomous driving system blush. However, solid-state batteries have the potential to make electric vehicles significantly more inexpensive and practical. Because of this, reporting on them can be challenging; nevertheless, we are seeing some encouraging news from Imec, a well-established research and development industry powerhouse situated in Belgium.

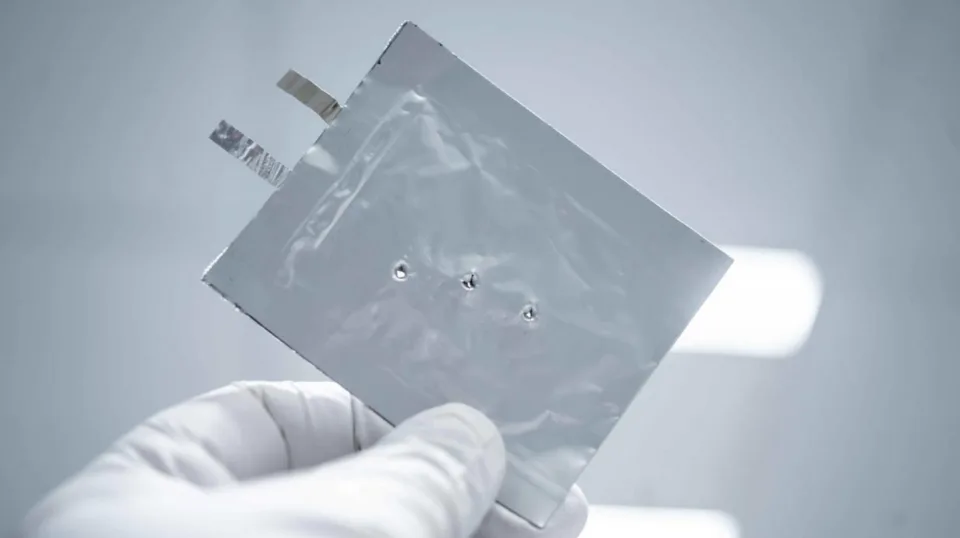

In the course of the SOLiDIFY project, the company that is financed by the European Union and its thirteen partners have created a prototype solid-state battery that has an energy density of 1070 Wh/L. This is about 25 percent greater than the energy density of the best lithium-ion cells, which is 800 Wh/L. Even more impressive is the fact that it employs a manufacturing technique that operates at room temperature, is compatible to existing lithium-ion battery product lines, and is anticipated to cost less than 150 euros (about $167) per kWh, in contrast to the approximately $140 per kWh that is currently being charged by batteries. “This process holds promise for affordable industrial transfer,” that is what Imec noted in a press statement.

It was a process known as “liquid-to-solid” solidification that was the breakthrough breakthrough. This indicates that the solid electrolyte of the prototype makes use of a “doped polymerized ionic liquid” coated in a thin layer measuring fifty micrometers. A high-capacity composite cathode is located on one side of the electrolyte, while a thin lithium metal anode is located on the other side. This configuration results in a battery cell stack that is relatively small.

In addition to overcoming problems related to mechanical strength and cathode impregnation, the collaboration was successful in increasing the charge rate of the cell to three hours and increasing its lifetime to one hundred cycles. Additionally, the utilization of cobalt was decreased as a result of the implementation of protective coatings that were nanometer-thin.

Clearly, there is a need for improvements in both the charging durations and the number of cycles (current lithium-ion automobile batteries can be charged 2,000 times, and some of them can be charged in well under an hour). Furthermore, in order for the technology to be applicable on an industrial level, it needs to undergo further scaling measures. On the other hand, it is worthwhile to put in the work because solid-state batteries have the potential to someday provide increased energy density, reduced charging periods, and enhanced safety, all at a cheaper cost.